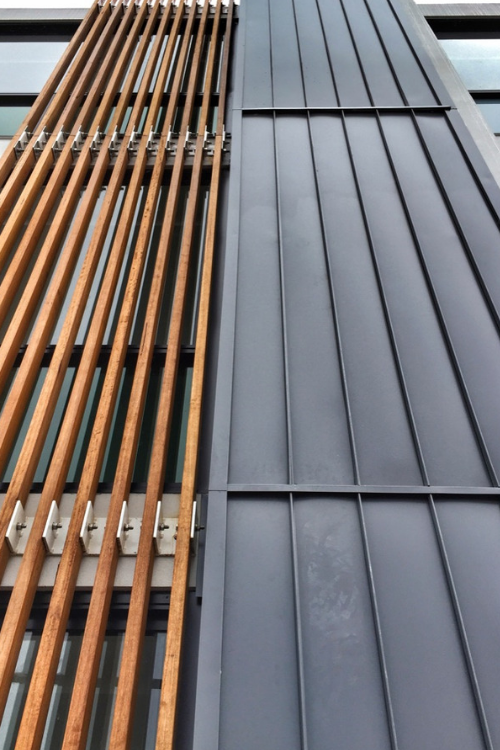

UrbanE™ Nail Strip is lightweight and promises extremely rapid and straightforward installation for real-time cost savings.

UrbanE™ Nail Strip requires continuous support. We recommend 15mm plywood for walling and 18mm plywood for roofs. For the 38mm x 265mm profile in Colorbond/Zincalume/Metallic/Ultra it can be installed on a 40mm batten at maximum 600mm centres. A ventilation gap is required to avoid the formation of condensation.

UrbanE™ Nail Strip panels are laid and fixed directly to the plywood substrate with concealed screws or nails along the perforated strip every 300mm.

There is no need for fixing clips and the additional operation of seaming. This ensures the speed and ease of installation whilst allowing for expansion and contraction

The female rib is simply pushed firmly onto the smaller male rib forming an effective water barrier and seal. We also recommend the use of a breathable vapour barrier between the plywood and steel panel.

With horizontal installations start to lay the first panel from the top and work towards the bottom with the male rib always at the top.

Screw fasteners through the centre of the perforated slots so that the sheets are able to adapt to thermal expansion and contraction.

As with all steel products you need to eliminate any potential material compatibility issues. Incompatible materials may include fasteners, adjoining panels as well as any adjacent materials that may direct water runoff onto the nailstrip panels. Incompatible materials may increase corrosion rates significantly for any steel product.